As a manufacturer of special machines, KOCH Pac-Systeme is a leader in know-how when it comes to the development and implementation of modular customised blister machines and packaging lines. The company from the Black Forest in Germany relies on simus systems in order to achieve excellence in business processes around SAP S/4HANA: So far, the collaboration between the two companies has led to the achievement of fast CAD part searches, high reuse, accurate costing, and the pre-migration classification and structuring of material masters. Read more

Posts

At a purchasing volume of several million Euro per year for machined parts, product developers should be well-informed about their manufacturing costs; because the rule of thumb is that 80 percent are determined in the product development stage. PI (Physik Instrumente) in Karlsruhe introduces simus classmate for this reason and integrates cost control directly to the CAD system. Read more

Marel, globally active developer and manufacturer of machines, systems and complete solutions for the fish, meat and poultry processing industry, is introducing the simus classmate software suite for automatic calculation and work plan generation. Since January 2021, the Boxmeer and Dongen (Netherlands) production sites are already successfully using the solution. In the first half of 2021 also Gainesville in Georgia (USA) and Gardabaer in Iceland are expected to go live.

Theegarten-Pactec in Dresden develops and manufactures packaging systems that can be configured individually. The introduction of simus classmate has been in progress since January 2019. Production Planning, Purchasing and Workflow Management of the mechanical engineering company should improve noticeably with the data management software.

KOCH Pac-Systeme, an expert on packaging machines, has trusted in simus classmate data management software since 2014. Design engineers can access the geometric similarity search as well as automatic analyses of their CAD models with the CAD module newly implemented in 2018 – and accelerate the design process significantly.

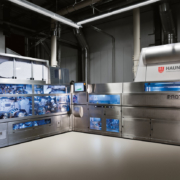

Hauni achieves transparency for a reduction of manufacturing costs at an early stage with CAD-integrated calculation software

In machines for filter and cigarette manufacturing alone, Hauni Maschinenbau GmbH based in Hamburg produces 30,000 new parts per year – each machine contains between 2,000 and 4,000 manufactured parts. In this case, transparency in manufacturing costs pays off: The CAD-integrated simus classmate software suite by simus systems currently calculates 80 percent of parts automatically with an accuracy rate of 95 percent.

Products

Solutions

- Master Data Governance

- Best Practice Process for Creating Material Masters

- Cost Calculation During the Design Process

- Generating Work Plans Automatically

- Automatic Classification of CAD Models

- Geometrical Similarity Search for 3D Models

- Automated Text Generation

- Supplier Selection for Purchasing Technical Equipment

Theegarten

Theegarten

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH