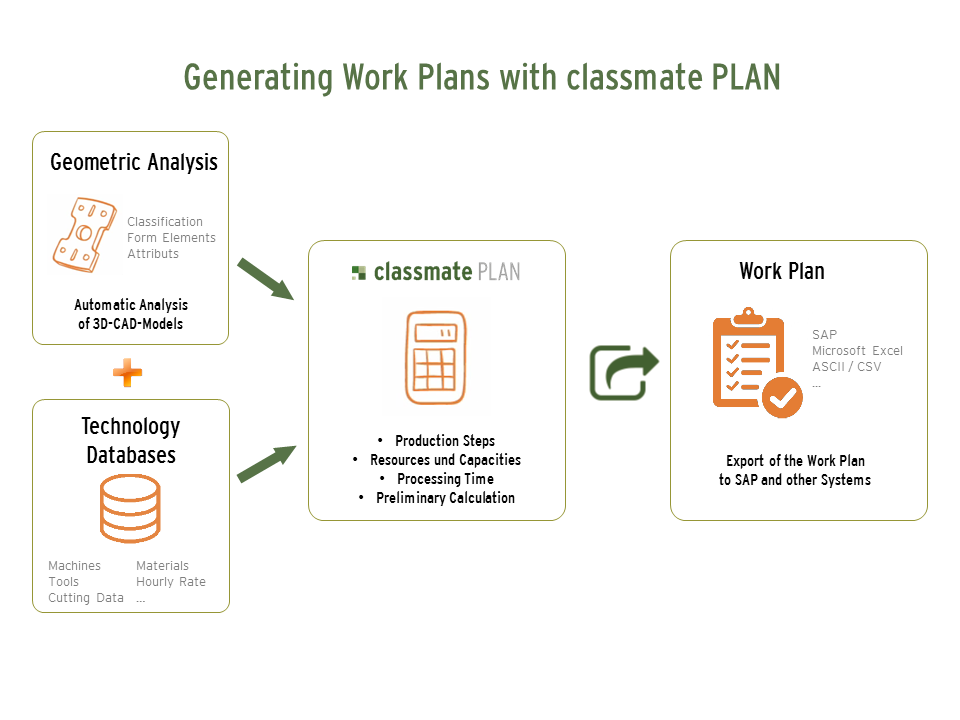

In a matter of seconds, classmate PLAN determines all possible and useful manufacturing alternatives under consideration of available parameters in the background. The user can now choose which of these alternatives will be used: The one with the lowest planned costs, the one with the fewest machine changes or the one with the shortest cycle times?

After calculating suitable machines, tools and production times with the in Germany commonly used REFA method (time study technique for the purpose of determining manufacturing costs), classmate PLAN uses the hourly rates and factors stored in the technology database to determine the manufacturing costs, as well as performing calculations on marginal and full costing. The user not only receives a fully functional work plan and information on manufacturing costs but also which price manufacturing partners need to quote based on full costs or marginal costs.

The results can be displayed visually on the graphic interface classmate FINDER. You can save, search for and compare several results. The effects of different structural solutions can be compared, e.g. a steel version followed by zinc coating in comparison to another version in stainless steel, the effects of a fit or a change of radius. All these changes are available in a matter of seconds. The various versions can be performed in the CAD model or, if unavailable, in the Viewer which is integrated in classmate FINDER and provides detailed information. Cost drivers or problem areas can be identified in list view, as well as through an automatic color coding in the viewer model.