High Spirits at Kiefel: Optimized Procurement Processes with simus classmate

The Kiefel GmbH partially automated their procurement process – and got support for the job from the data management specialist simus systems. The company now benefits from automatic cost calculation with the help of the simus classmate application as well as automatic vendor assignment.

Based in Freilassing, Bavaria/Germany, Kiefel has been on of the market leaders in design and manufacture of plastics processing machines for more than 60 years. The company employs approximately 1,200 members of staff on their sites in Germany, the Netherlands, Austria, and the Czech Republic and develops plants for numerous well-known companies worldwide. Kiefel has already been using the simus classmate software suite for data management since 2011; since the spring of 2018, it also supports processes in Procurement.

Head of Procurement at Kiefel, Franz Maier, explains the history of the implementation: “As a plant manufacturer, we depend on parts from external partners. Therefore, technical procurement naturally takes on an important role for us. Processes such as supplier selection, demand and bid appraisal of basic parts have taken up a lot of working hours until now.”

“In simus classmate, we found a solution that relieves us of time-consuming procedures and allows our members of staff to focus on more complex parts and jobs with the support of automatic processes.”

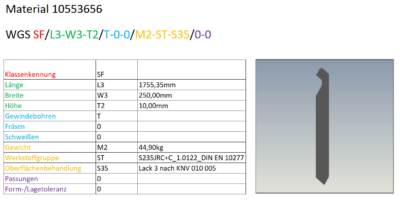

The company uses the automatic parts analysis for this which the application generates on the basis of CAD models: It takes geometric form elements such as outline and internal contours and drill holes but also parameters such as finish quality or material into account. The software amalgamates data and generates a material group key for each part. The key abbreviates all information on the parts to an ID.

Furthermore, Procurement can determine the manufacturing costs of parts reliably with the classmate plan software module – only using the 3D CAD models. The analyzed part is also compared to similar parts from the purchase order history. Specific data, e.g., material costs, machining times, or special surcharges are also incorporated into the evaluation. Procurement has now access to qualified price calculation.

All manufacturing partners of Kiefel were transfered to a vendor database for supplier screening. Information such as available resources and labor costs as well as additional information on manufacturers are stored here. classmate PLAN uses the material group keys and the vendor database to find those businesses which possess the required technologies and capacities to produce the part concerned.

After a plausibility check and risk assessment by classmate, a suitable supplier is selected. classmate PLAN then automatically transmits all information to SAP, so the order only needs to be approved in the established automatic order process.

“Instead of spending a lot of time on demand and bid appraisal process or supplier selection for basic parts, our staff can now concentrate on processing complex parts and tasks thanks to classmate PLAN. The software enabled us to reduce the process times and gain more time for our colleagues for more difficult and therefore more labor-intensive tasks.”

“Automating simple, repetitive tasks, faster availability of materials and happy staff – this is how intelligent procurement should look like!”

Franz Maier sums it up.

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH