Success story – Supfina: Limiting overwhelming number of parts long-term

As a provider of high tech solutions for automated manufacturing and superfinishing systems, Supfina noted an increase in the number of parts despite their variant management and building blocks for parts. A classification project in collaboration with simus systems GmbH from Karlsruhe, Germany, helped with data cleaning. Subsequently, the flood of product data was limited effectively by the simus classmate software suite. Apart from an increased efficiency in design, new potential benefits could be implemented in many places in the company.

Supfina Grieshaber GmbH & Co. KG develops, manufactures and distributes systems from metal-cutting superfinishing technology for perfect surfaces world-wide. Approximately 40 projects are implemented in close contact with clients from the automotive, roller bearing and precision industry. A long time ago, the company from Wolfach (Germany) and its 200 employees developed a site in North Kingston (USA) and representation in Beijing (China) as a provider of customized automation solutions including robotics: “It is our goal to optimize our clients’ advantages and to include our experience at an early stage in order to find a solution,” Christoph Siegel, CEO of the solutions provider says. Markus Müller, Head of Mechanical Design (CAD/PDM) at Supfina adds: “I see our main advantages in the fact that we are listening to our clients and can meet their requirements. ”

Looking for classification experts

Müller expected the same from service providers who were supposed to help him manage the flood of parts in design. Particularly the tools of superfinishing machines which were developed for a client’s part were designed all over again because similar parts or predecessors could not be found in the inventory. Despite the variant system and building blocks for assemblies, the number of new parts increased from 2,200 to about 4,000 per year. In the preselection process, three providers qualified who got the chance to present their solution on a range of parts. But only two providers met the requirements. These approaches were evaluated based on 41 criteria with points. simus systems won by far: “simus does not only understand the DNA of the similarity search,” says Markus Müller.

“The company from Karlsruhe, Germany, is particularly focused on the result to meet clients’ requirements and always find a solution. That is a good match for us.”

Successful induction project

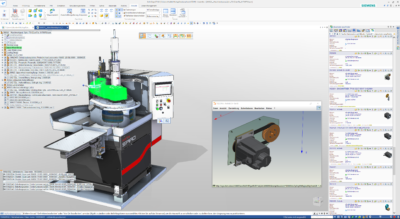

After the first workshop together, simus systems provided the initial classification of the existing parts. “Using common methodology, tagging and classification took a lot more work which would require several years”, Markus Müller says. The simus classmate software automated this process. In this process, similarities in geometry of the 3D models from Solid Edge were considered as well as the existing meta data and information from other sources, such as the PDM system PRO.FILE by ProCAD. On this basis, more workshops on classes and new processes for dealing with data followed.

“Everyone involved approached the project with a lot of expert knowledge and it worked beautifully,”

Müller says. “But in the first year, we discovered potential for improvement in the process and developed new requirements.” The initial classification was further “sharpened” and the CAD processes were optimized, which automatically classified new parts and existing parts were found. Within the cooperation with ProCAD, simus systems developed a close integration with the PDM system PRO.FILE. Many ideas by Supfina were picked up and implemented. Müller said:

“Despite the long duration of the project, simus systems’ project budget was met. It says a lot about the provider, if they are also reliable in those terms.”

With the help of the overview and direct access to such interchange parts, the number of new parts was limited.

Sustainable data cleaning

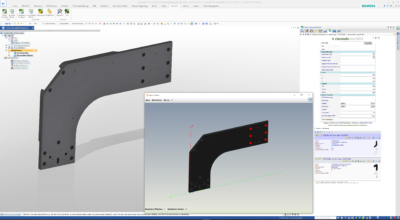

The customized development approach by Supfina requires that all parts are represented by 3D data, even the approximately 30 percent purchased parts. Today, the approximately 30 CAD users access a database consisting of 203,460 parts and 88,980 assemblies, which is in pristine order. The designers can open classmate easyFINDER directly in the Solid Edge user interface – a web-based search engine which combines numerous geometrical and text-based search options. A geometrical partial match search finds all parts containing these features for a highlighted geometrical area.

“An unbeatable feature. The hole pattern plan of a part alone can find the wanted counterpart in seconds.”

Thanks to the integration with the PDM system, users can obtain the part they found directly from PRO.FILE and use it in Solid Edge. Despite the creative and customized product development at Supfina, the key performance indicator for the production of new parts compared to new projects was lowered. And the growth rate of the active inventory of parts is now continuously maintained at 4,000 which had blatantly risen before. With simus classmate, the effect of the data structure and classification could be secured for several years to come. Markus Müller says:

“The employees now had to implement the new way of working consistently, a deciding factor in our success was the solution’s high ease of use.”

Beneficiaries across the entire company

The improved indicators signify an economic use of parts as well as the elimination of wastefulness, not only in product development and design but in numerous downstream areas. The consolidation and bundeling of quantities ordered in purchasing or the decrease of capital formation in the warehouse are part of it, just like the optimization of numerous processes in the company. The flexible simus classmate software suite is capable of development and opens up numerous opportunities. In a project that has recently been finalized, the identifiers for discontinued and special components were introduced which helps the designers to work economically with the range of parts. “We will also transfer warehouse identifiers to simus classmate,” says Markus Müller. “Stocked parts can be found this way and be used in line with their status as standard, special or discontinued part.”

What helps the designers, should also be used for acquisition and purchasing: In classmate easyFinder, predecessor parts can be found using the internet and provide conclusions on suppliers and prices and therefore optimize order processes. Furthermore, the classmate PLAN module will be evaluated, which analyzes parts and assemblies by work steps which are calculated for a virtual machine park. Therefore, make or buy decisions can be made based on solid data.

Positive development

The time needed for adjustments, support of the 30 users, salvaging of errors and strategic questions about extensions and upgrades are estimated at less than 200 hours per year by Markus Müller. If he needs support, he likes to ask simus systems.

“The competent project engineers take on the question with a purpose-oriented approach – no matter when or who I call.”

For upcoming software upgrades, he decides on the application on a case to case basis in accordance with simus: “The project engineers explain to me in an open manner which added value a new version would provide for Supfina, even if it should be rather small for once.” In previous years, Markus Müller was not only pleased with numerous new features, the performance of the software was also increased significantly:

“The software was developed further with palpable vigor including the user interface, calculation algorithms and the speed.”

Photo credits: Supfina Grieshaber GmbH & Co. KG

simus systems GmbH