As a manufacturer of special machines, KOCH Pac-Systeme is a leader in know-how when it comes to the development and implementation of modular customised blister machines and packaging lines. The company from the Black Forest in Germany relies on simus systems in order to achieve excellence in business processes around SAP S/4HANA: So far, the collaboration between the two companies has led to the achievement of fast CAD part searches, high reuse, accurate costing, and the pre-migration classification and structuring of material masters. Read more

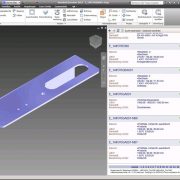

Gessmann GmbH in Leingarten, Germany, uses the simus classmate software suite to improve the reuse rate of CAD models – which also leads to cost reductions in downstream areas. Based on the same data, a calculation accompanying the design is directly integrated into the CAD system – but Work Scheduling and Purchasing should also benefit from it.

As a provider of high tech solutions for automated manufacturing and superfinishing systems, Supfina noted an increase in the number of parts despite their variant management and building blocks for parts. A classification project in collaboration with simus systems GmbH from Karlsruhe, Germany, helped with data cleaning. Subsequently, the flood of product data was limited effectively by the simus classmate software suite. Apart from an increased efficiency in design, new potential benefits could be implemented in many places in the company.

Windmöller & Hölscher (W&H), a manufacturer of machines and production lines for flexible packaging operating worldwide, uses the simus classmate software as the basis for global Value Management. A transparent database and automated processes that already facilitate the assessments of costs in the concept phase, lead to a reduction in the diversity of parts and provide Purchasing and Production with valid target costs for throusands of new parts every month. The solution created by simus systems integrates with the existing CAD, PLM and ERP systems.

The collaboration of Hermann Schwelling Maschinenbau (HSM) and simus systems, expert for management of technical mass data and software developer of simus classmate, started in 2007 with the classification of 175,000 material masters alongside the introduction of SAP. Read more

HEKUMA counts on simus systems for the classification of its master data and work plan generation. The high performance automation company from Eching, Germany, puts their trust for classification of their master data and work plan generation in the professional support of the simus systems GmbH and their software solutions. Read more

Higher Quality for Millions of Master Data Records

The Krones Group, global market leader in packaging and bottling technology, uses simus systems GmbH expertise in classifications to improve the quality of their master data. A tailored classification, an automated data classification and a user-oriented search engine support plant manufacturers in reducing the complexity of the parts database and keep the creation of material masters to a minimum. The newly structured range of parts, which was relieved of duplicates, contributes to reducing administration costs company-wide.

Products

Solutions

- Master Data Governance

- Best Practice Process for Creating Material Masters

- Cost Calculation During the Design Process

- Generating Work Plans Automatically

- Automatic Classification of CAD Models

- Geometrical Similarity Search for 3D Models

- Automated Text Generation

- Supplier Selection for Purchasing Technical Equipment