In preparation for its migration to SAP S/4HANA, Rhaetian Railway in Landquart, Switzerland, revised its 180,000 material master records for rolling stock, catenaries, tunnels and bridges with simus systems. The pilot project already revealed that the software and methodology provided by simus classmate would be indispensable for the main project. Following the successful classification and migration of 108,000 records, the system is now being used in construction, maintenance and materials management to quickly search for and create new materials, assign classes and automatically generate short texts. Read more

As one of the three leading application specialists in conveying and compression of gases, Aerzener Maschinenfabrik GmbH (AERZEN for short) produces high-performance blowers and screw compressors for industrial application. In order to increase efficiency and keep its promise for quality even more extensively, the company has been working on improving master data quality for about ten years. Using software and services by simus systems, a classification was build and a systematic master data creation process was created in integration with SAP. Read more

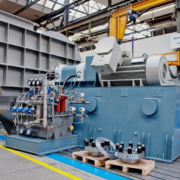

simus systems has advised Piller Blowers & Compressors GmbH in setting up a classification and prepared master data for a migration of the ERP system to SAP S/4HANA for approximately two years.

In this process, all of the master data was revised and significantly reduced. simus classmate was introduced for the purpose of classification and master data maintenance: User-friendly tools synchronize the data directly with the ERP system.

The collaboration of Hermann Schwelling Maschinenbau (HSM) and simus systems, expert for management of technical mass data and software developer of simus classmate, started in 2007 with the classification of 175,000 material masters alongside the introduction of SAP. Read more

As an international network of technology businesses, Putsch GmbH & Co. KG with its headquarters in Hagen, Germany, was facing a new generation of information technology. The company for machinery and equipment with a focus on the sugar industry used the opportunity of switching systems from PPS and PDM to improve their master data. The expert simus systems used the software simus classmate to support them in this pursuit. After the migration in ERP and PLM software by SAP, simus classmate automated the classification and text generation.

As a supplier of highly productive, ecological as well as safe and reliable machines and systems for road construction, the Ammann Group based in Langenthal, Switzerland, strives for close contact to their clients worldwide. With the assistance of simus systems GmbH, Karlsruhe, Germany, the company creates a consistent, structured database for the ERP system by SAP. The clear data structure of all materials allows automated translation of article texts into 12 languages. The company will achieve more efficiency and a genuine internationalization.

For over ten years, KSB AG, one of the world’s leading manufacturers in the pumps and valves market, optimizes its master data in the ERP system by SAP with the support and the software of simus systems in Karlsruhe. Worldwide processes were accelerated, the IT system landscape was harmonized, a consistent level of knowledge established, platforms for product development created and global cooperation was improved with new processes.

Zeppelin Systems GmbH, Friedrichshafen, Germany, the industrial branch of Zeppelin, migrated their master data to a new ERP system by SAP with the help of simus systems and their software solution classmate DATA. Read more

Higher Quality for Millions of Master Data Records

The Krones Group, global market leader in packaging and bottling technology, uses simus systems GmbH expertise in classifications to improve the quality of their master data. A tailored classification, an automated data classification and a user-oriented search engine support plant manufacturers in reducing the complexity of the parts database and keep the creation of material masters to a minimum. The newly structured range of parts, which was relieved of duplicates, contributes to reducing administration costs company-wide.

Products

Solutions

- Master Data Governance

- Best Practice Process for Creating Material Masters

- Cost Calculation During the Design Process

- Generating Work Plans Automatically

- Automatic Classification of CAD Models

- Geometrical Similarity Search for 3D Models

- Automated Text Generation

- Supplier Selection for Purchasing Technical Equipment

Piller Blowers & Compressors GmbH

Piller Blowers & Compressors GmbH