Success Story KSB AG: Optimizing Master Data as the Basis for Globalization

For over ten years, KSB AG, one of the world’s leading manufacturers in the pumps and valves market, optimizes its master data in the ERP system by SAP with the support and the software of simus systems in Karlsruhe. Worldwide processes were accelerated, the IT system landscape was harmonized, a consistent level of knowledge established, platforms for product development created and global cooperation was improved with new processes.

As one of the leading manufacturers of pumps and valves, the KSB AG based in Frankenthal, Rhineland-Palatinate (Germany), has production sites and assembly locations in 16 countries. The closely-knit distribution network reaches across more than 100 nations. Approximately 800 product lines arranged in 70 product groups for water transport systems, wastewater treatment and conversion of energy, as well as process engineering and building services, fulfill country-specific requirements of numerous industries in various forms. In the financial year of 2015, approximately 16,000 staff members generated a turnover of over 2.3 billion euro.

‘KSB has been in existence for 140 years and has been operating globally for 75 years,’ says Karlheinz Steier, who is responsible for strategy processes and structures. ‘We have spent the past years becoming a producer with a global network.’ Local systems were replaced by global systems, material masters prepared for migration and worldwide processes and tools created to monitor them. simus systems contributes to this endeavor with their software suite simus classmate and numerous services since 2004.

Material Masters Classification for SAP

The cooperation started with the support in developing a class model and the introduction of a management system of classes and features for SAP 4/5. It was supposed to operate as a leading system but the interface for designers needed to be more user-friendly, flexible and efficient. ‘Designers tend to think in table structures and are not necessarily a fan of maintaining individual datasets as set up by the SAP standards,’ Karlheinz Steier says. The only recently established company at the time, simus systems, benefited from exchanging information as much as KSB did – a win-win situation.

‘simus systems put our requirements into practice extremely quickly and flexibly,’

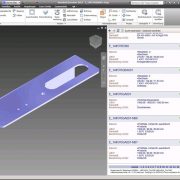

Karlheinz Steier recalls. Since then, the simus classmate software has been used as a management system of classes and features for several SAP clients. It is based on an efficient data model which deals with characteristics and features proficiently. The project with an extend of 1.2 million material masters was very successful. The class model supported the implementation of the CAD interface to SAP during the introduction of the 3D CAD system Unigraphics (currently NX by Siemens PLM Software) in 2005. Furthermore, designers can search material masters directly with classmate FINDER by simus systems.

Material masters classification and basic data are kept separately in SAP. It was a logical step to extend the easy-to-use search of classmate FINDER from classification data to basic data. Data maintenance in table view was also more suitable for editing large amounts of data. simus classmate was therefore enhanced by the creation and maintenance of basic data in SAP from 2007 to 2009. ‘In the next step, logistical data for individual sites was also included,’ Joachim Pahlen, Director of Methods/Structures at KSB says.

‘The number of datasets, which can be maintained by simus classmate, has increased to 6.4 million.’

International Modular Product System

International Modular Product System

It was the groundwork for the next bigger project with simus systems – a modular product system for a ‘global product’ that can be produced worldwide on all sites. ‘Not only does KSB produce multiple models but also takes customers’ individual requirements into consideration,’ Joachim Pahlen says. ‘For this reason and for the various development methods and tools within the company, it was a big challenge.’ At an early stage, the product idea is being examined and the ideas and development steps become more concrete and at the end of the process, provisioning processes supply the product information – in the form of a design BOM, engineering BOM and basic data in SAP. In the past, data sources and data differed regionally.

High variance and configuration do not seem to be compatible naturally. simus systems already knew and material masters in their complexity and was therefore a suitable partner for a connection to a complexity manager that is used to model product variations and assign parts based on rules.

‘The complexity manager is meant to get knowledge out of the heads of designers and put into rules,’

Karlheinz Steier says. The variant window is defined by features and parts are grouped on the basis of their material master classification and rules. The features and parts were available – the rules as to how to group parts had to be defined. In 2012, water motor and standardized chemical pumps could be released as the first global products. New products for new markets were supplemented, the class system was developed further continuously. ‘Meanwhile, 800 classes are grouped into material masters, there are 4,300 features in the product development process,’ Peer Höpner says, who is tasked with methods and structures. You can find local as well as global products in the global product portfolio – usually, local variations must be substituted by global ones. Furthermore, the necessary conditions were created in order to optimize products by regions.

‘By now, there is transparency of what happens in other parts of the world and we can prevent that two or three sites are developing the same thing. We can therefore standardize globally and make use of development capacities in a more targeted way,’

Joachim Pahlen says.

Alignment of IT Landscape

IT systems also had to be aligned – in the sense of a merge to a global SAP system. SAP was implemented gradually as the ERP system on the production sites – so far, 80% of sales are processed via the central system. Ranging from standard production, individual transactions, heating pump, power plant pumps to valves, all business is based on one data model. This also brought some administrative challenges: ‘Different local databases containing basic data cannot be overseen from one central location in the world,’ Joachim Pahlen says. Instead, central rules were developed which are implemented locally. Various centers are authorized to generate material masters. ‘In order to assure the quality, classmate DATA gives us strong routines,’ Karlheinz Steier says. You can generate weekly or daily reports to see if processes are not done within the guidelines, duplicates were created or documents are missing.

‘The architecture of the software works well for us, as you can create new tools in the ‘toolbox’ and use them depending on the customer’s needs without any help from simus systems,’

he adds. Six licenses from this ‘toolbox’, classmate DATA, are used on three German sites – 150 users are accessing classmate FINDER via Citrix in order to search datasets for features, texts or geometrical features quickly. Changes on the datasets in classmate FINDER are transferred to SAP directly. Furthermore, you have a direct link from the classmate FINDER interface to SAP.

Longstanding Cooperation

The working hours for IT and the department for these tools are estimated to be less than 0.5 FTE by KSB.

‘The value for money as well as the quality of the delivered software have always met our standards,’

Peer Höpner says about the collaboration. simus systems pays close attention, takes the customers’ requests into consideration and integrates appropriate improvements to the standards so that all customers can benefit from them. ‘Special customer-specific requirements were also implemented successfully and in time,’ says Karlheinz Steier, ‘simus systems has never been the cause for any delays.’ KSB’s members of staff are always very satisfied with the implementation speed and personal support. Even KSB’s IT Department has always been happy to consult simus systems when it came to create or check ports to SAP. Peer Höpner emphasizes the flexibility of the applications:

‘While the software architecture has grown with us over the years, it is still flexible and adaptable.’

There are more innovative ideas for the future to improve processes – for example the standard factor costing or the geometrical similarity check. ‘We are watching advancements of simus solutions closely,’ Karlheinz Steier says: ‘Our journey together has not come to an end yet.’

Images: KSB AG

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH