Success Story – Gessmann: Transparency in CAD Data and Manufacturing Costs

Gessmann GmbH in Leingarten, Germany, uses the simus classmate software suite to improve the reuse rate of CAD models – which also leads to cost reductions in downstream areas. Based on the same data, a calculation accompanying the design is directly integrated into the CAD system – but Work Scheduling and Purchasing should also benefit from it.

The safe handling of cranes, industrial trucks, rail vehicles and ships often comes from one source – operated by a joystick manufactured by W. Gessmann GmbH in Leingarten, Germany. The global market leader provides standard solutions from catalogs as well as customized products ranging from individual sticks to integrated pults, control consoles, and to entire crane control units. Furthermore, the Gessmann portfolio also entails customized automatically guided vehicles (AGVs) and software to increase efficiency of production companies. The safety-critical hightech products are developed, designed, partially assembled, and exported globally by around 600 employees at the headquarters near Heilbronn, Germany. For a high degree of ergonomics, safety, and quality, the company relies on production depth: Tool-specific metal and plastic parts are produced on own tools, machine-specific components are machined on state-of-the-art CNC machines in the factory where electronic components, such as THT and SMD components are assembled. “By merging mechanical, electronic, sensor technology, and software, the development of products becomes more and more detailed,” Martin Eggensperger, Head of Development in Mechanics and Electronics, explains. The development team consisting of 50 people is very well-equipped with 3D CAD, E CAD, PDM, Document Management, and ERP.

A modular structure, wide choice of joysticks, and a variety of electric interfaces are characteristic for the industrial joysticks by Gessmann.

Pushing Digitalization

A progressive company constantly rethinks processes and introduces improvements. Years ago, Martin Eggensperger had already identified two challenges: “With about 5,000 new CAD parts per year, it is equally wise as it is difficult to find similar parts in the database. Furthermore, we wanted to increase the accuracy of our estimate for manufacturing costs during the design process.” Wilhelm Doberstein, whose tasks as a mechanics developer and designer include precalculation, examined the market for calculation software and stumbled over simus classmate by simus systems:

“The software convinced us because it integrates to existing systems, different areas are linked, and the desired processes are completely digitized.”

After a pilot project, software testing by IT, interface descriptions, setting up of a test database and checking the possibilities for implementation led the negotiations at the beginning of the year 2021 to a purchase decision.

Complete crane control units for special purpose vehicles are also developed in line with customer specifications.

Finding CAD Models Faster

A kickoff at the end of April 2021 started the first project stage in which the basics for the search for CAD identical parts and the database were supposed to be created. A team of four people set up the server structure for simus software, then the connection to the ProFile PDM system was implemented with external support. All 3D models were converted to simus’ generic data format and imported to the system’s database. At the same time, a set of criteria was developed to assure useful search results derived from data.

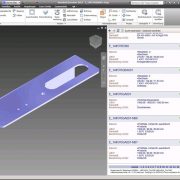

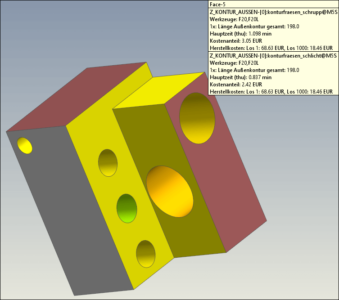

Simus systems analyzes 3D CAD data by geometry in a patented process and sorts it to geometric clusters. In addition, the software automatically calculates a ‘geometric fingerprint’ which allows for a quick similarity search and even an easy search by geometric segments.

The data was matched to the ERP system to assign materials and their price information. The PDM system now manages approximately 100,000 records and provides an improved reuse rate for parts in new processes. An important tool to avoid duplicates and decrease design work was received by about 20 designers after training: easyFINDER, a webbased ‘search engine’, is opened directly from the interface of the 3D CAD system Solid Works, opens up many opportunities for fast search options in PDM data since November 2021.

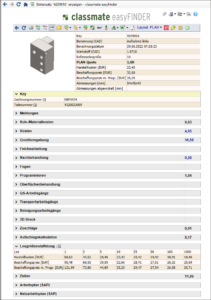

classmate easyFINDER shows all relevant parts of a search in a clearly presented way – including all cost details.

Reuse Through Transparency

This resulted in significantly increased transparency:

“Instead of going through numerous drawings or searching the database, users can list all relevant parts in one search filter with one click in 10 seconds,”

Martin Eggensperger says. “It was well-accepted as it was much easier and quicker.” Those, who want to continue modifying a model that they found can check it into Solid Works for further use right away. For each part, all information required for further use is available at a glance. Due to the increased reuse rate, not only was the work on design unnecessary but subsequent costs in Purchasing and Manufacturing are void.

Calculation During the Design Process

The costs are also concerned in the currently ongoing introduction of the classmatePLAN calculation software. It analyzes CAD models based on their geometry and further parameters, such as dimensions, materials, tolerances, and surface finish. On these grounds, work sequences, technologies, machining centers, and further frameworks of the manufacturing processes are automatically recommended. To ensure a high degree of accuracy, a lot of data has to be ascertained in detail beforehand. A total of six workshops with the individual manufacturing areas serve to define the required parameters and specifiy cost rates. Due to the distinct production depth at Gessmann, milling and turning parts, pressing, laser welding, and cutting, drilling, thread cutting, as well as finishing and other surface finishes are concerned. On assembly level, two different assembly processes are included. Two of the workshops have already taken place.

Safe Work Scheduling, Precalculation, and Postcalculation

The routings suggested by classmatePLAN should also facilitate work scheduling. “The tool has already been tested here and the employees are looking forward to it,” Martin Eggensperger says. The routings contain the machines that are actually required and resources for the detailed cost rates including setup times. “In our practical experience, everyone calculates it differently, you can easily miss one borehole or counterbore,” Wilhelm Doberstein says. “The human aspect is eliminated by classmate PLAN.” easyFINDER, as a webbased tool, provides designers, work schedulers, and purchasers with access to a consistent calculation bases and can therefore trace the respective results.

“Simus systems helps us to expedite our digitization projects quite well,”

Martin Eggensperger sums up. “The collaboration works very well, communication is easy, our wishes are implemented within the time and cost constraints.”

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH