Success Story Putsch: Structure of an Automatic Classification

As an international network of technology businesses, Putsch GmbH & Co. KG with its headquarters in Hagen, Germany, was facing a new generation of information technology. The company for machinery and equipment with a focus on the sugar industry used the opportunity of switching systems from PPS and PDM to improve their master data. The expert simus systems used the software simus classmate to support them in this pursuit. After the migration in ERP and PLM software by SAP, simus classmate automated the classification and text generation.

The Putsch Group’s core competencies are in planning and building sugar plants, refineries and machines for the production of sweeteners. Grown over 140 years, the company designs and produces the whole product range from the reception and preparation of sugar beets continuing to shredding, juice purification, sieving and filter machines as well as machines for sugar extraction and shipment. They are mostly dealing in custom-built machinery for the international market. Customer focus and after-sales-service are of great importance. ‘We are processing many orders for replacement parts for machines and equipment from the 1960s onwards,’ Rüdiger Bromm, Technical Manager of Research & Development at Putsch says.

‘Quick and safe access to all stock lists and BOMs – for recent development also CAD models – is essential for our business. This can only be achieved reliably with professional classification.’

New Generation of IT Systems

In 2006, the 2D design with AutoCAD was already replaced by 3D modeling with AutoDesk Inventor. All drawings and documents for the articles were managed in the PDM system Productstream Professional (PSP). In the course of the planned replacement of the PPS system running on AS400 by SAP ERP 6.0 in 2015, this solution should be replaced by SAP PLM. So far, it was possible to research and retrieve the articles with a descriptive number and titles consisting of 60 characters which was also visible on the drawings. ‘SAP uses a neutral material number which excludes this option,’ Rüdiger Bromm says. ‘This is the reason we had to establish a clearly presented classification before we could use the SAP functions.’ All for One, providing the service of implementing the ERP system, made Bromm aware of the software specialist simus systems in Karlsruhe, Germany, who supports the business in structuring, optimization and maintenance of technical mass data. Rüdiger Bromm was initially interested in the cost and the possibilities to derive a classification from the existing master data and CAD models. In 2014, Putsch already carried out a pilot project in order to get a clear picture of the starting point, required steps and costs.

Amortization in a Year

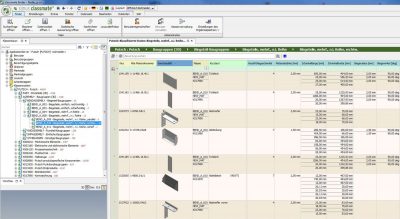

In the course of this project, the master data of about 37,000 articles including descriptions from the AS400 were read out and declared as leading. The BOMs from PSP were added and linked to them by article numbers. Finally, 1,200 of the about 30,000 CAD models from Inventor were analyzed for testing purposes. A basic classification was created with the article master data which corresponded to the simus best practice classification with regard to standard and purchased parts. About 20,000 articles have already been processed with various techniques in order to get an estimate on the targets, the required expenditures and the expected Return on Investment. On Putsch’s request, the project was organized in three phases – the actual classification, the introduction of automatic text generation and the CAD integration of simus software. These three phases were introduced to Management by Rüdiger Bromm including the expectations for cost and benefit. ‘I actually wanted to have the budget for the first step authorized,’ Rüdiger Bromm recalls. ‘But our CEO approved the funds for all three phases immediately, as the investment calculations determined that the costs would already pay off within the first year.’

Project Runs Smoothly

The project started with a joined workshop, in which all aspects of the service as well as the simus classmate software to be introduced were examined. In the first phase, the functional classification of the master data and the geometrical classification of the CAD data could be completed on schedule and the data transfer to SAP could be prepared. After the introduction of SAP in February 2016, the data was processed and the simus systems software was fully implemented.

‘simus systems’ support was very good, working together went very smoothly. Our consultant was educated in the field, well-prepared and had qualified answers to all our questions,’

Rüdiger Bromm reported. In total, 43,000 parts were classified and the material masters were imported using a rule. This included all legacy data which had been active in previous years.

High Reuse Rate

Ever since then, each of the 15 CAD workstations has access to the geometrical search engine classmate FINDER.

It opens up various possibilities for users: Free-text search is an option, as well as structured search in the class tree, but also a search for geometrical similarities of 3D models which can even be limited to certain faces. ‘Getting quick and easy search results motivates staff to look for existing solutions before creating a new design,’ Rüdiger Bromm states. ‘We could increase our reuse rate significantly this way.’ Not only does it avoid unnecessary duplicates raising process and material costs, the search for suitable models for quick modifications also increases efficiency. A new production machine was finalized a lot faster than expected because many related parts were found quickly and could be modified easily. ‘The cycle for new developments has become faster overall,’ says Bromm.

It opens up various possibilities for users: Free-text search is an option, as well as structured search in the class tree, but also a search for geometrical similarities of 3D models which can even be limited to certain faces. ‘Getting quick and easy search results motivates staff to look for existing solutions before creating a new design,’ Rüdiger Bromm states. ‘We could increase our reuse rate significantly this way.’ Not only does it avoid unnecessary duplicates raising process and material costs, the search for suitable models for quick modifications also increases efficiency. A new production machine was finalized a lot faster than expected because many related parts were found quickly and could be modified easily. ‘The cycle for new developments has become faster overall,’ says Bromm.

‘simus software helps us to use 3D technology more efficiently.’

Automated Text Generation

To keep the master data quality on the achieved level, a Quality Assurance Division was set up at the beginning of the year. Heiko Schneider, the Quality Assurance Manager, and his team ensure that all descriptions, abbreviations, values and specifications are created by valid rules, no matter if the articles are manufactured in-house or externally. Once the groundwork is done, simus classmate takes care of the automatic generation of short and sales texts based on the classification rules. This way, data entry errors are eliminated and consistent master data is created. ‘With the automatic short text generation, we achieve more structure, transparency and efficiency,’ Heiko Schneider comments. ‘The standardization of spelling by clear rules facilitates the search even on the workstations without a CAD system.’ classmate FINDER is also used more frequently there.

‘This software is crucial for our section. Compared to SAP, it definitely facilitates finding and maintaining data,’

Rüdiger Bromm says.

Catalyst of the 3D Design

Not all possibilities are exhausted yet – some processes could be accelerated even further, for example by programming user-friendly interfaces between classmate FINDER and Inventor individually. But the main advantage, editing CAD model search results directly, already pays off. The experience with ten newly developed machines in the past year and a spectacular profit due to a 3D printed prototype proved the chosen path to be a good decision: ‘The coherent concept of using different software which works well together is worthwhile,’ Rüdiger Bromm says. ‘With the help of simus classmate as the central data management system, we can achieve significantly faster product cycles.’ Therefore, an expansion of the installation is planned – for example in a newly opened facility in Wuppertal.

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH