As one of nine innovation centers worldwide, the Océ Printing Systems GmbH & Co. KG in Poing near Munich, Germany, develops, produces and markets digital high performance printing systems with related workflow and software solutions. With the support of simus systems and their calculation tool classmate PLAN, the global market leader in the field of continuous printing keeps an eye on the costs of parts even during the design process. Accurately determined calculations open up opportunities to changes on short notice and comparisons of parts in development. Furthermore, the print expert benefits from generating faster and more accurate quotes.

Venlo, Vancouver and Poing – this is where you can find the main production sites of the Dutch printer manufacturer Océ who is part of the Canon Group based in Tokyo since 2010. Europe and America are part of the main markets. In Poing, 1,000 employees produce high-end print solutions tailored to the needs of international customers. Apart from print, these solutions for professional document management include the documentation and archiving of datasets as well as maintenance and service. These processes are regulated by the in-house software Océ PRISMA. Many customers have an enormous print volume, for example insurance and health insurance companies or tax authorities. Although the durable printers can print 160 – 5000 sheets per minute depending on the demands, these industries replace print more and more with digital media. This is why Océ already started the production of print systems for new markets ten years ago, for example for poster, wallpaper or canvas print.

Venlo, Vancouver and Poing – this is where you can find the main production sites of the Dutch printer manufacturer Océ who is part of the Canon Group based in Tokyo since 2010. Europe and America are part of the main markets. In Poing, 1,000 employees produce high-end print solutions tailored to the needs of international customers. Apart from print, these solutions for professional document management include the documentation and archiving of datasets as well as maintenance and service. These processes are regulated by the in-house software Océ PRISMA. Many customers have an enormous print volume, for example insurance and health insurance companies or tax authorities. Although the durable printers can print 160 – 5000 sheets per minute depending on the demands, these industries replace print more and more with digital media. This is why Océ already started the production of print systems for new markets ten years ago, for example for poster, wallpaper or canvas print.

Equipped for Future Challenges

To ensure their success, the company did not only extend their range of products but also cut their costs. An example is classmate PLAN by simus systems from Karlsruhe, Germany – an integrated solution for standard factor costing. Beforehand, a comprehensive calculation for in-house production of parts was only available after completing the design. Moreover, these were calculated manually. Both delayed planning and providing estimates unnecessarily. For this reason, the printer expert was looking for a solution to simplify the calculation process. In January 2011, simus systems was invited to Poing. Using Océ sample data, the IT expert presented their first results in March of 2011. During this time, Thomas Jäger, Team Manager in industrial engineering joined as project manager and contact person for simus systems: ‘At first, classmate PLAN calculated all values using default values. We wanted to refine the search for everything that generate costs and increase the accuracy of search results.’ The new requirements included working steps, cycle times and exact calculations for individual parts. An interface to the CAD system Pro/Engineer was implemented. Further refinements in dealing with tools and cutting data were optimized. The growing requirements and how to realize them were discussed in workshops and tested in prototypes, so the software finally met all requirements for the rollout in October 2012. Since that time, other customers benefit from the new standard product by simus systems, too.

Thomas Jäger says:

‘simus systems has faced the new challenges successfully. You can feel the drive for constant improvement.’

Cost Control Before Production

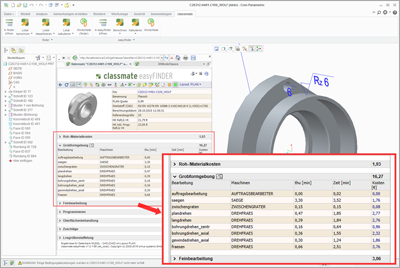

A new product goes through design, production scheduling, prototype phase and finally production. Océ uses classmate PLAN in the first two stages of the process. With a total of 50 licenses, about 30 designers regularly work with the tool as the primary user. Even during the design stage, they have an overview of the costs – without any additional work. Integrated in the CAD system, the software calculates all costs for the part at the push of a button without additional input. Users can check if they are within the budget at all times. The benefits are clear to Thomas Jäger: ‘The user interface is self-explanatory, anyone who is used to using a computer can handle classmate PLAN. This ease of use quickly leads to a widespread use.’ The preliminary calculations and the working plans they are based on are available for export in various text and spreadsheet formats.

A new product goes through design, production scheduling, prototype phase and finally production. Océ uses classmate PLAN in the first two stages of the process. With a total of 50 licenses, about 30 designers regularly work with the tool as the primary user. Even during the design stage, they have an overview of the costs – without any additional work. Integrated in the CAD system, the software calculates all costs for the part at the push of a button without additional input. Users can check if they are within the budget at all times. The benefits are clear to Thomas Jäger: ‘The user interface is self-explanatory, anyone who is used to using a computer can handle classmate PLAN. This ease of use quickly leads to a widespread use.’ The preliminary calculations and the working plans they are based on are available for export in various text and spreadsheet formats.

classmate PLAN Works in the Background

The program generates working plans based on the geometrical specifications, whose degree of details can be determined at your discretion. At this stage, every part is allocated all times for processing, set up, intervention and tool change by defined rules. In addition to the component geometry, the tool analyzes tolerances and surface properties in the CAD system directly. The program determines the category automatically, for example bent sheet metal parts or turned parts. Depending on the dimensions, e.g. those of shoulders, milled pockets or fittings, the software structures the production in its individual working steps including the required machinery and tools. The production costs are then calculated for these determined procedures. This is done with the help of class-specific rules from databases containing information on machines and machining processes (technology databases). The partial results originating from this process are used to derive various estimates such as costs per working step or ideal batch sizes. classmate PLAN generates a complete calculation within a few seconds. ‘With this approach, we achieve savings as the cheapest option can already be pursued further during designing,’ says Thomas Jäger. In the medium term, consistent monitoring is a deciding factor in the development of costs.

Further Optimization in the Future

Océ will only use classmate PLAN to its full potential in the future. Apart from the integration to the CAD system, an interface to the ERP system SAP is planned. The plans become even more efficient as factors such as raw material prices, design bases and rates are retrieved from the business-related database directly. Make or buy decision are made easier for Purchasing.

The assembly mode of classmate PLAN is intended to be put to wider use. Based on the prices of individual parts, subassemblies and assembly time, the software module calculates the costs of an entire assembly. Thomas Jäger explains: ‘We would like to increase the level of detail for the assembly mode for this purpose.’ The current priority is put on the introduction of further modules of the classmate line planned for 2016: With the full package consisting of classmate DATA, CAD and FINDER, the company gains a combination of user-oriented search software, automatic classification of master data and 3D models.

‘This extension will save us working hours and contribute to more cost transparency. Planning purchases would also benefit from this,’ Thomas Jäger remarks and adds: ‘The excellent assistance of our project manager Dr. Weißkopf always leads to good results. I am from the technical sector and noticed that we speak the same language.’

In user group meetings, they responded to the client’s individual needs, Thomas Jäger thinks. Otherwise, he is also impressed by the software developer’s service: ‘In March 2015, we could update our version 5.2 to 7.1 without any issues. Thanks to the new interface, we achieved an even better look and feel. We are looking forward to working with simus systems.’

Copyright: Océ Printing Systems, Poing

Screenshot classmate PLAN: simus systems, Karlsruhe