Success Story by HSM: Small Steps Lead to Major Data Benefits

The collaboration of Hermann Schwelling Maschinenbau (HSM) and simus systems, expert for management of technical mass data and software developer of simus classmate, started in 2007 with the classification of 175,000 material masters alongside the introduction of SAP.

In several projects that followed, effective solutions for automation were created which have now amounted to convenient and companywide workflows creating and maintaining material masters simus classmate proves to be a flexible and user-friendly solution which fits seamlessly into the SAP environment.

More than 45 years ago, giving the company his name, Hermann Schwelling founded Hermann Schwelling Maschinenbau, known as HSM, based in Frickingen, Germany, near Lake Constance. The idea behind it was to reduce the volume of reusable materials, such as paper, carton, plastics and many other materials in order to return them to the recycling loop in a more effective way. Since then, the family business has developed balers which reduce the volume by 95 percent using up to 150 tons of press capacity. At the same time, HSM developed shredders for paper and data storage mediums, such as CDs, credit cards and hard drives which cover secret services up to security level P-7. Approximately 900 employees and more than 100 service and sales centers are the basis for a network which serves thousands of customers worldwide.

Solid Database as Foundation

Recycling and compressing data was also the focus when the company introduced SAP’s ERP system in 2007. “Nine months before the live start, all existing material masters were supposed to be classified, so we would be able to adopt them into the new company software in a structured way,“ says Hubert Kötzinger, Chief Technology Officer at HSM. “Six years of man-year laid ahead of us which we were unable to do on the side“. He could offer simus classmate to the board as a solution which would reduce this work down to a sixth.

During the SAP-introductory project, the software modules classmate CAD and classmate FINDER were implemented with Solid Works at the CAD workstations which allowed for automatic classification based on 3D geometries and additional information. In several common workshops, existing data was analyzed and a new class structure was developed and finally assigned to all material masters. “The completed class structure in simus classmate could be synchronized with SAP in time for the live start,“ Hubert Kötzinger says. “Some material masters were still assigned to the wrong classes but the overall result was an excellent start.“

Generating Automatic Purchase Order Texts

The collaboration was continued in a project for automatic generation of purchase order texts. The idea behind it was to generate purchase order texts for materials automatically from defined features in a class in simus classmate. Technology and strategic purchasing defined the required textual patterns for the relevant classes based on the features, simus systems developed suitable rules. As soon as the new texts reached the level of information of the existing ones, the texts were updated in SAP by placing a status indicator.

“You gain a lot of flexibility and new opportunities arise if you can control SAP via simus classmate,“

Hubert Kötzinger says. He killed two birds with one stone: The time and effort spent on the maintenance of purchase order texts by the departments involved went down to zero – and designers maintain the classification with an increased level of motivation which in turn grants high data quality.

Traceability in Mechanical Engineering

Mechanical engineering companies such as HSM continuously work on improvements of their product lines – their standard series as well as special machinery with customized configurations. But how do you get an overview which products are affected by concrete changes? Conversely, how do you find out which innovations went into a certain product? “We couldn’t answer these questions directly using SAP,“ Hubert Kötzinger reports. “Traceability is vital these days due to many reasons ranging from quality assurance, supply of spare parts to service.“ Together, he and simus found a convenient solution. The validity of BOMs is controlled by SAP change master records. As SAP does not offer a convenient solution for the analysis of change master records and the affected BOMs, a separate data destination was set up and the BOMs were assigned to material masters which made the relevant where-used lists and bill explosions possible. This shows when which changes were introduced to which products. Additionally, you can find the relevant assemblies in simus classmate and their BOM can be exploded to individual parts.

“In the search, it helps me a lot that you can see which parts an assembly consists of in the preview,“

Hubert Kötzinger says. “It is a very convenient way to answer initial questions.“

Gradual Successes in Automation

Several additional projects followed which produced a deeper integration of the installed software. The database of the Software Engineering Base was connected to SAP by classmate which supports creating parts. A standard part library was also integrated in simus classmate and generating product descriptions for customs and the maintaining customs tariff numbers were automated. simus classmate also provided a solution to add data relevant to name plates to finished products. “The ERP system is too static for these automation solutions,“ Hubert Kötzinger adds. This is why these projects become extremely costly.

“simus classmate on the other hand supports the process with its flexibility and generates a high information density.“

For a medium-sized to industrial scale company with 900 employees, this was particularly important. “We have to work in a very structured way while also avoid the slowness of big companies.“

Creating Material Masters with Quality Gates

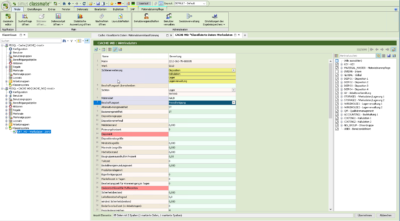

Mandatory fields which have to be completed when creating material master records are highlighted in red.

Mandatory fields which have to be completed when creating material master records are highlighted in red.A good example for this is the recently completed project of a continuous material master creation process with simus classmate. Each special department of the company, ranging from Engineering to Marketing, has to be in a position to create and maintain materials. Each material goes through various defined process steps which simus classmate named ‘quality gates’ until its definition reaches completion. A drawing part is defined in Engineering and passed on to Production Planning by changing the status where the procurement type will be decided and for purchased parts, Purchasing will add more views. Up to seven departments can be involved until materials are created to completion.

“Using SAP for maintenance, there were different interpretations which fields were to be maintained by whom. simus classmate allowed us to implement a material masters maintenance process,“

Hubert Kötzinger says. Some basic data, for instance, can only be entered by the designer and cannot be changed thereafter. “To prevent errors, we would have to newly define the authorization concept of the ERP system down to field level – which requires a lot of time and work.“ Furthermore, the material master data quality was supposed to be improved and the maintenance process was supposed to be set up in a more simple and flexible way.

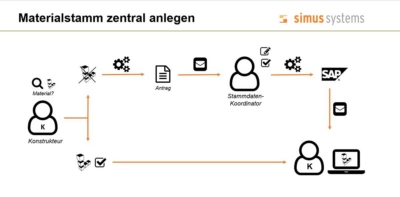

Easy Workflows Defined

In cooperation with simus systems, a solution to use classmate Finder as the frontend for the maintenance process in SAP was developed, an application which has since been installed on 100 workstations based on the classmate database which production data from various SAP material views was added to. For each type of material, workflows were created which lead the material through the specific creation process. After a status change, the link of the material to be maintained is moved to the next folder which creates the workflow by assignment of folders. If Production Planning works on materials in your folder, the views to be maintained will be displayed after the procurement type is specified. By choosing views, mandatory fields are specified by systems of rules and default values are set depending on the material type. HSM achieved automation and sets of algorithms for the creation process by these means. “Everyone can complete their workload efficiently,“ Hubert Kötzinger says.

“Hence, many potential errors are prevented before they occur.“

Not only does it work by handing out authorizations for folders by department but via the automatic process network and the extensive use of available information. Depending on the material type, a “Master Data Quality Gate“ in which simus classmate walks you through step by step was set up for each department involved. In each sub-step, the defined state is synchronized with SAP and only approved after completion. Having 210,000 material masters, each improvement in data quality, convenient data maintenance, and security of processes counts. “Employees quickly got out of the habit of working with SAP,“ Hubert Kötzinger says. “Due to the high level of acceptance, we could finally disable these functions in there.“

Additional Automated Projects Set Up

Since then, experts at HSM are already working on new projects. One is concerning the company website which shows nearly all machines. simus classmate was supposed to add 200 features of the 1,400 articles for sale available so that the website reflects the state of current technical data daily as well as the graphic representation of products.

The automatic translation of material description as well as the automatic generation of spare parts catalogs or calculations which accompany the design process are in preparation.

“When introducing simus classmate in 2007, we could not have imagined all the things we were able to automate and optimize,“

Hubert Kötzinger concludes.

“We reached a high level of data quality, efficiency and information density.“

Image: HSM GmbH + Co. KG, Frickingen

Chart: simus systems GmbH

Theegarten

Theegarten

Theegarten

Theegarten