Marel is digitizing costing and routing with simus classmate

Marel, globally active developer and manufacturer of machines, systems and complete solutions for the fish, meat and poultry processing industry, is introducing the simus classmate software suite for automatic calculation and work plan generation. Since January 2021, the Boxmeer and Dongen (Netherlands) production sites are already successfully using the solution. In the first half of 2021 also Gainesville in Georgia (USA) and Gardabaer in Iceland are expected to go live.

Like most manufacturers, Marel is striving towards cost-conscious design, reduce the time it takes to create routings and set target costs for contract parts. In 2019, a group of engineers from all major production sites began searching for software that would automatically provide work plans and a calculation of future manufacturing costs based on 3D models and component information to identify potential improvements. The common platform should be available to design as well as production and procurement. “When there were only two names left on the long list of potential suppliers, we started a pilot project with simus classmate,” reports André Kouwenberg, Global Manufacturing Engineer at Marel.

“Based on the results, we chose simus systems as a strategic partner for the implementation, which is now supporting us very flexibly in the optimisation.”

Many workshops including designers, cost engineers, mechanical engineers, procurement and the new partner simus systems took place. New processes were defined and a technical database was filled with all internal and external production techniques and machining parameters. Due to the cellular structure of the production, the automatic creation of production routings was quite a complex task. By automatically classifying the 3D models based on feature information, the products are now assigned to the right production cell in Boxmeer or Dongen. In the process, routings are already created for the correct machines and operations within the production cell.

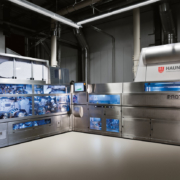

On the left the Marel classification on material group codes is displayed, while the right shows the BoM structure with 3D views.

Marel’s IT department created connections to SAP and the Product Lifecycle Management (PLM) system. The challenges of a multi-CAD environment were successfully overcome in the process.

“With the cost information in the development phase, we now improve the design engineering of our products, while manufacturing saves time and effort in creating production routings. Procurement achieves better terms with suppliers, due to target costing capabilities”,

says André Kouwenberg. The partners see interesting approaches for future cooperation in simus systems´ possibilities for master data optimisation.

Photo credits: simus systems GmbH

Theegarten

Theegarten

Hauni Maschinenbau GmbH

Hauni Maschinenbau GmbH Piller Blowers & Compressors GmbH

Piller Blowers & Compressors GmbH